Detection Technology

Precautions for partial discharge tester

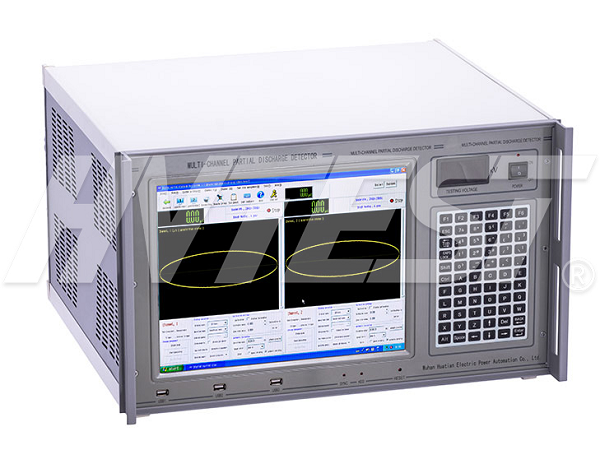

Partial discharge testers are widely used in power testing. Partial discharge test is the main test item for the insulation of power equipment. When using the partial discharge tester to test, what aspects should be paid attention to? What are the safety tips during the test of the partial discharge tester?

1. The test site voltage of the partial discharge tester is as high as tens of thousands of volts, and the test personnel should strictly abide by all safety precautions. There should be obvious and clear warning signs in the test area, and everyone on site should be aware of the high-voltage area. Direct test personnel should understand all live components and high-voltage components in the measurement circuit, and those who do not directly test should be isolated outside the test area. During the test and after power-on, no one is allowed to enter the high-voltage area.

2. The test site should be tidy and clean, and other irrelevant items should not be stored. There should be no messy small metal pieces (such as bare copper wire segments, screws, nuts and other small metal pieces) on the ground in the high-voltage range. The tested product, step-up transformer, coupling capacitor, etc. should be kept at a proper distance from the surroundings.

3. The surface of the test product, step-up transformer, coupling capacitor, etc. should be kept dry and clean, because moisture and dirt on the surface will cause partial discharge on the surface and cause abnormal measurement.

4. The test operator should master the test circuit, test method, test procedure and test purpose. Before starting the test, connect the lines according to the regulations. Various metal objects in the test area should be firmly grounded, and then check and improve all possible discharge parts in the test area (if there are no sharp or acute angles), pay special attention to the grounding line , Whether the wires of high-voltage lines and strong current circuits are firmly connected.

5. Avoid exposing the connecting wires to prevent corona discharge, especially for partial discharge tests with higher voltage levels. If necessary, thicken the high-voltage connecting wires and install an anti-corona cover to reduce the excessive field strength. Caused by corona discharge. The shielding cover should not be in contact with the porcelain skirt of the test product.

6. Under normal circumstances, during the test, the partial discharge of the test product during the withstand voltage and pre-boost is much larger than the normal value. At this time, the instrument will inevitably exceed the full scale. In order to prevent damage to the instrument, the coarse gain adjustment knob of the instrument should be turned counterclockwise by one or more steps, and the standard is not to exceed the full scale. When the voltage drops to the measured voltage, turn the coarse gain adjustment switch clockwise by one or more gears to record the measured value.

7. When the test is abnormal, the power supply should be cut off before further processing.

Pneumatic test transformer | 2021/9/2 | reading645time How to use the clamp ground resistance tester | 2021/9/1 | reading673time return