Detection Technology

Precautions when using partial discharge detector

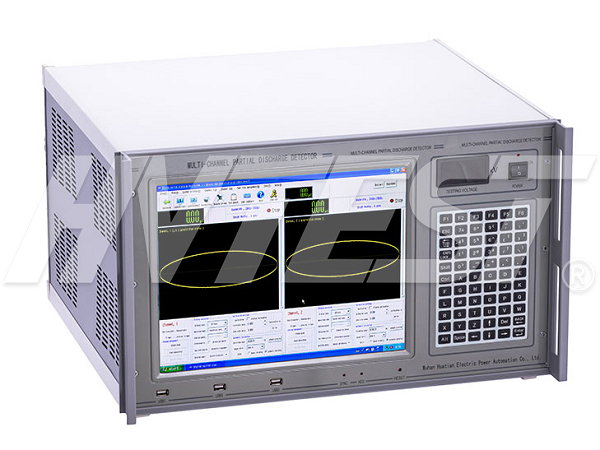

When a partial discharge is generated under the test voltage, a pulse current is generated by the coupling capacitor, and the pulse signal is picked up by the input unit. After the required frequency band is selected by the low-noise preamplifier and filter amplifier, and the main amplifier is amplified, the baseline is scanned on the ellipse of the oscilloscope screen The discharge pulse is displayed on the top, and it is also sent to the pulse peak table (logarithmic table) to display its peak value. The time window unit controls the working time of the pulse peak meter in each cycle of the test voltage, and highlights the display of the display during this period, and the width and position can be changed, which further strengthens the anti-interference ability.

The partial discharge tester is a new type of instrument developed and produced. The instrument has the advantages of high sensitivity, large dynamic range of the amplifier system, wide range of test samples, and easy operation. And adopts advanced anti-interference components and unique gate display circuit, strong anti-interference ability, and has four kinds of high-frequency ellipse scanning. The partial discharge detector is suitable for the type of high-voltage products, factory test, new product development test, motor, mutual inductance Quantitative testing of partial discharge of electrical appliances, cables, bushings, capacitors, transformers, arresters, switches and other high-voltage electrical appliances. It can be used on site by manufacturing plants, scientific research departments and electric power departments.

Precautions

1. Before the test starts to pressurize, the test personnel must check the circuit in detail and comprehensively to avoid wrong connection of the circuit. Test whether the grounding wire of the instrument is firmly connected to the grounding body. If the connection is not firm or the wire is kicked off by the foot when the head is pinched during preparation, this may cause personal and equipment accidents.

2. Avoid exposing the connecting wires to prevent corona discharge, especially for partial discharge tests with higher voltage levels. If necessary, thicken the high-voltage connecting wires and install an anti-corona cover to reduce the excessive field strength. Caused by corona discharge. The shielding cover should not be in contact with the porcelain skirt of the test product.

3. Under normal circumstances, during the test, the partial discharge of the test product during withstand voltage and pre-boost is much larger than the normal value. At this time, the instrument will inevitably exceed the full scale. In order to prevent damage to the instrument, the coarse gain adjustment knob of the partial discharge detector should be turned counterclockwise by one or more gears, so as not to exceed the full scale as the standard. When the voltage drops to the measured voltage, turn the coarse gain adjustment switch clockwise by one or more gears to record the measured value.

The loop resistance tester encountered a problem | 2021/6/11 | reading695time Description of megohmmeter terminal | 2021/6/10 | reading695time return